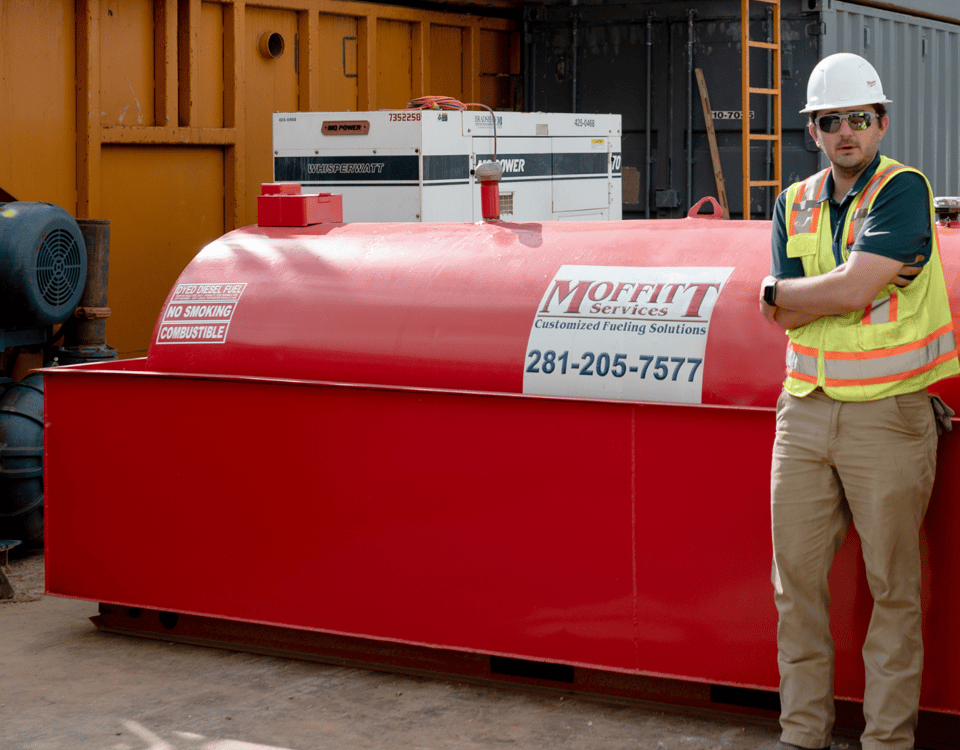

Fuel powers our operations at Moffitt Companies, driving our delivery trucks and heavy haul equipment. Therefore, we understand the critical importance of maintaining safe fuel storage and handling practices. This blog post dives into comprehensive fuel tank care, focusing on inspections, maintenance, containment, and equipment tips. We want to ensure everyone understands the importance of fuel safety.

Inspecting for Integrity

Regular inspections are the foundation of any good fuel safety program. In fact, catching problems early prevents larger, more costly issues later. Check your fuel storage tanks regularly for any signs of damage. Look for rust, dents, or leaks. Specifically, pay close attention to the tank’s seams, welds, and fittings. Inspect the surrounding area for any signs of spills or leaks.

Maintenance Matters

Cleaning and maintaining fuel tanks keeps them working properly. For example, sediment and debris can build up over time. This build up contaminates the fuel and damages equipment. Schedule regular cleanings based on the tank’s usage and the type of fuel stored. Additionally, use the right cleaning methods and materials to avoid damaging the tank itself. Check and replace any worn or damaged parts, like valves and seals. This proactive approach minimizes the risk of leaks and spills, and bolsters fuel safety. It is recommended that many of these tasks be performed by skilled technicians, to insure operations are performed safely and within manufacturer specifications.

Containment: Protecting the Environment

Containment pans are essential for preventing spills from reaching the ground and polluting the environment. Most notably, check these pans regularly for cracks, leaks, and debris. Make sure they can hold the maximum volume of any potential spill. In short, clean containment pans after any spill, and regularly as part of your maintenance routine. Ultimately, proper containment protects our soil and groundwater, and ensures fuel safety.

Keeping Pumps and Systems Running Smoothly

Pumps and other fuel handling equipment also need regular care. Check pumps for leaks, unusual noises, or vibrations. Verify that all connections are tight and secure. Moreover, maintain filters and strainers to keep contaminants out of the fuel. Lubricate moving parts as recommended by the manufacturer. Proper equipment maintenance keeps our systems running smoothly and improves overall fuel safety.

Preventing Contamination

Keeping fuel clean is another important part of fuel safety. To this end, keep tank openings and vents clean and free from obstructions. Make sure to use proper filters and breathers to prevent moisture and dirt from entering the tank. In addition, make sure fuel delivery systems are clean and free from contaminants. Use dedicated equipment for different fuel types to avoid cross-contamination and ensure the integrity of the fuel.

Spill Prevention

Preventing spills is crucial for protecting our environment and resources. It is important to train employees on proper fuel handling procedures. Make sure that teams have the correct equipment and resources to prevent spills. Additionally, create clear plans for responding to spills, including containment and cleanup procedures. In essence, a well-trained team and clear procedures greatly reduce the impact of accidental spills. As a result, fuel safety is increased.

Moffitt Companies: Committed to Fuel Safety

At Moffitt Companies, we’re committed to fuel safety. We understand that safe fuel handling and storage are critical for our operations and the environment. By following these guidelines, we minimize risks and ensure that our fuel systems operate safely and efficiently. We hope this information helps everyone understand the importance of comprehensive fuel tank care.